From Habitat magazine - issue 33, colourful person

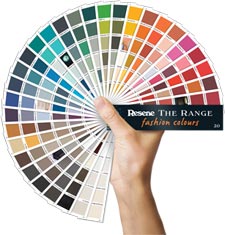

A look behind the curtain at what goes into making Resene's colour charts and fandecks.

Have you ever taken a close look at a Resene colour swatch before? Unless you are a design or paint professional, you may not have even realised that the colour you are holding isn't just a highly accurate representation of what your chosen paint hue is going to look like – it's the real thing. You also might not know that Resene's commitment to providing true representation of their paint colours on their swatches, charts and fandecks is quite unique. In fact, Resene is the only company in Australasia who Color Communications Inc Australasia (CCIA) produces charts for who uses their own actual paint on their colour chart swatches.

It's to be expected that when you're producing something that no one else is, especially on a large scale, there is a lot of extra effort and specialised equipment that is required to see it through. But much of making it happen comes down to two key individuals: Dianne Connell, Resene's Colour Controller, and Dean Viljoen of CCIA.

As Colour Controller for the past 30 years, Dianne is the one who maintains the overall control of Resene's meticulous colour standards. Every two years, she works with Resene's marketing team to monitor the progression of colour trends and identify the hues that will make up the latest edition of the Resene The Range fashion colours fandeck and helps to update other charts or create new ones as needed. It's a big task, one that includes researching potential new colours, selecting which ones will get mocked up, working through the laboratory formulas and approving proofs of the final colours. Each fandeck takes over 12 months from first research to finished fandeck.

While Dean has 12 years under his belt helping Resene with their colour cards, colour systems and colour marketing tools, CCIA have been manufacturing these items for more than 30 years. All those years ago, Resene was their very first customer. Operating out of East Tamaki, Auckland, CCIA is a leader in the manufacturing of colour marketing tools for the decorative and industrial markets across the Asia-Pacific region, including colour cards, colour swatches, fandecks and complete colour systems.

"The manufacturing of colour systems is complex, and each step in the process requires a very high attention to detail to maintain the necessary level of quality," says Dean.

Each new or updated Resene colour chart or fandeck begins with a plan. Dean and CCIA liaise closely with Dianne and Resene to set the parameters for the project, including the type of colours required, layout, artwork, printing and quantity specifications, to name a few, to determine everything that's required for manufacturing.

"There are many stages in the manufacturing process, but it all starts with getting the colour right," Dean explains. "While there are some charts where we use specialty paints like Resene FX Metallic and textures, Resene SpaceCote Low Sheen paint is used for the majority of the swatches we make for Resene."

Dean and Dianne collaborate to make sure each hue meets Resene's exacting colour standards. The colours are proofed using a given film thickness and substrate, then the mixed colours are measured on a spectrophotometer before undergoing a careful visual check. Adjustments are then made until the correct colour is achieved."

Once the colours are approved by Resene, they are ready for the next stage – which is the coating process. This is done on a purpose-built knife over roll coating line. The coating process uses continuous rolls of various substrates and coats the paint using a precise and constant film thickness. The paint then passes through a heated oven to ensure it is fully dry before it is cut into sheets at the end of the coating line."

The next steps of the process include cutting the sheets into paint chips, printing, creasing, finishing, slitting, mounting and packing – each process and the time it takes is dependent on the type of colour chart or fandeck being produced, the number of colours and the quantity we're making. Manufacturing a chart from start to finish generally takes about eight to ten weeks but can take much longer."

So, the next time you hold a Resene colour swatch in your hands, take an extra moment to marvel and appreciate that that little rectangle has made quite the journey and passed some pretty scrupulous standards to make sure you'll know exactly what you'll be bringing home in your next paint tin.

Did you know...

Most paint companies use printer ink colour matches on their colour charts? Printer ink performs differently under lighting, compared with paint, due to the different make-up of the materials – this is called metamerism. By using real Resene paint on colour charts, the colours look true to colour so what you see on the Resene chart you will get on your wall. Remember to test your colour with a Resene testpot – as lighting, sheen level and other colours in the space can change your perception of a colour.

Search habitat magazine stories

Printed copies of habitat highlights are available from late March 2024 at Resene ColorShops and resellers, while stocks last. You can view back issues of habitat magazine online.

Specifiers:

If you have an idea, project or story that you think would suit habitat, we’d love to hear from you. Please drop us an email with your details and include photos if submitting a project.

Sign up for a DIY card and Save! Australia | New Zealand